Mechanical bats, PATS drones

Many greenhouse entrepreneurs are bothered by insect pests in their crops on a regular basis. This story is mainly about moths, a pest that we try to keep under control as much as possible.

The moth-er, of a lot of problems

Insect pests are the thorn in the side of many crop managers. Aphids, thrips, spider mites, nematodes, caterpillars and moths: we'd much rather live without them. Here we mainly zoom in on moths, a pest that we try to keep under control in greenhouses where we grow mature plants. These so-called “mother plants” are attractive to moths, as the moth caterpillars like to nibble on the tasteful leaves. Though we’d prefer they wouldn’t.

Chemicals have been available for decades to combat moth infestations, but these are no longer an option in food production. Not only we, but many of our fellow horticultural entrepreneurs are therefore eagerly looking for more sustainable solutions.

The pied piper, of moths

Jim de Jong (working at Koppert Cress for 5 years) is following a avanced professional education as a cultivation expert and says: “You have to imagine that a moth lays about 700 to 1000 eggs in its life. When these eggs hatch, 1000 caterpillars spread over the crop. They eat a lot. And they don't just eat the whole leaf but take a bite from different leaves. As soon as those caterpillars turn into moths, it really starts to turn into a huge problem. At one point it was so bad that we walked around the greenhouse with 4 to 5 people every morning with badminton rackets to, you guessed it, manually catch the moths. Our record was 60 moths in one day, but it takes an hour with such a group. Not at all efficient. I’d like to see that differently."

Biological crop protection

Colleague Henk Grashoff, who has been with Koppert Cress for 12 years. With many more years of horticultural experience behind his name (and surprisingly enough, once started his career as a pastry chef), adds: “We try everything to get the moths under control. There are multiple ways to do so. We can focus on the eggs, for example by introducing Macrolophus (predatory bugs) and Trichogramma (parasitic wasps). These parasitize the eggs so that no caterpillar is formed. We can also combat the caterpillars that are already there with biological bacteria. And as soon as the moth starts flying, there are, for example, trap lamps that attract and roast the moths. There are also pheromone traps: the males approach the pheromones and stick to a sticky plate. By catching the males, obviously fewer new moths are produced."

Prevention is better than cure

Organic crop protection, trap lamps and pheromone traps; it sounds like a whole range of solutions, but they are not good enough. Cultivation Manager at Koppert Cress, Ronald Vreugdenhil, explains: “If we add everything together, we go a long way in capturing the moths, so we get them under control, but it mainly results in a lot of labour and high costs. We would like to change that. That is why new solutions are always welcome."

Three bright minds, and other titles

Fortunately, the PATS drones team, founded by Kevin van Hecke and the brothers Sjoerd and Bram Tijmons, is trained in electrical engineering, aerospace engineering and business administration respectively. Even though it is good decorum to state the academic titles before their names, we think that their character traits may say more about how they use their intelligence to add value to the horticultural sector.

Kevin van Hecke

Kevin developed an interest in physics and electrical engineering early in life and found his equals at the Technical University in Delft. Kevin: "When I saw students in the middle of the arrival hall between the electrical engineering and physics building, taking things apart with the sound of hard drives in the background, I knew this is the place for me."

It was not long before his professors started calling him "the liberated atom," and that "title" provided him with an interesting project, to say the least. Armed with ambition, courage and Star Wars comparisons, Kevin worked on programming and testing the very first self-learning robot in the International Space Station.

Sjoerd and Bram Tijmons

Sjoerd and Kevin got to know each other in the MAVlab (Micro Air Vehicle Laboratory) at TU Delft where they worked on the smallest possible, autonomous drones. When Sjoerd came in one day, after he hadn't slept well due to the presence of mosquitoes in his room, it all clicked: “Can't we use drones to shoot mosquitoes from the sky?”

When they were younger, Bram and Sjoerd had already fantasized about starting their own company but were still looking for a good business case.

Bram: “We started doing some odd jobs in the attic and did a demo here and there. The tests we did were technically successful, but while the idea of mosquito-hunting drones is fantastic, the accompanying noise from flying and the cameras on the drone raised questions about the invasion of privacy in the bedroom. We decided that we first wanted to develop the product further in a place where we would be less hindered by privacy legislation.”

Reaching new heights, Metaphorically and practically

A series of new possibilities unfolded when an acquaintance pointed out to Sjoerd that the horticultural sector is dealing with many flying pests.

Kevin: “All three of us are not from the Westland area, but we have lived close to the greenhouses all this time. Yet we had never been inside one. The image we had was of people on their knees planting flower bulbs, but once we entered, we were overwhelmed by the number of robots. Only then did we realize the possibilities here and how greenhouse horticulture really is the business card of the Netherlands to the world. We are proud that we can strengthen the connection between the Technical University and the horticultural sector.”

Hunting for pests

It did not take long before they sat down with Glastuinbouw Nederland, an organization that represents 70% of the total greenhouse horticulture acreage in The Netherlands. This brought them into contact with a variety of growers, their crops and their problems.

Bram: “It was not very difficult to find places to initiate testing. We started in the Cyclamen cultivation and later in the pot roses. We decided to focus on moths, because they are relatively large, so the camera system can detect them well. More importantly, the damage that moths cause to many crops is significant, which is actually positive for our business case.”

And so, the development of PATS and their reputation in the horticultural sector took off. They started with practical tests and you could not think of an innovation event where they were not asked to talk about the somewhat coarse but therefore surprising way of crop protection.

Practice tests at Oranjeveld

During Fruit Logistica in Berlin, they came into contact with Rob Baan, the owner of Koppert Cress. The PATS team was given a tour of the company, excited colleagues about their ideas and soon started large-scale practical tests at the Oranjeveld location. That was February 2019.

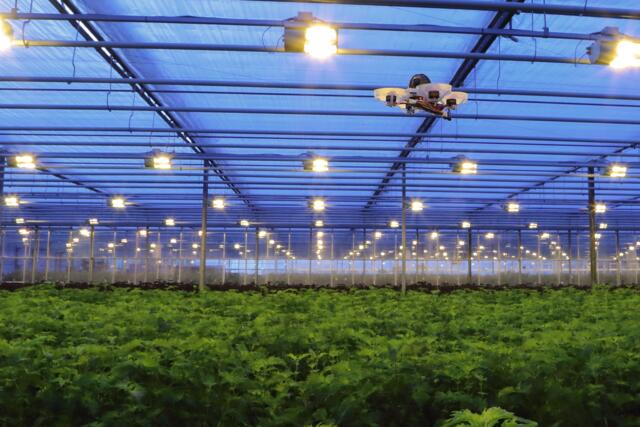

Kevin: “A system consists of a camera system, a drone, and a charging platform. These three things work together to fight the moths. The camera detects the moth, the system calculates the flight and then the aim is for the drone to fly autonomously against the moth to disable it. Our learning path consisted of the questions: can we see the moths, can we track them, can we count them, and can we eliminate them? We have been working on that in the past year.”

Mechanical bats

Bram: “At one point we ran into the situation that the drones, that were targeting the moths, scared them off. This made them try to flee, just like moths try to avoid bats in nature. Now you may be thinking, "Then why don't you just hang up bat hives?" We thought so at one point, but bats are "unfortunately" a protected species, so they cannot be used in crops. But it is very logical; just as you have biological bats in nature that eat moths, in the greenhouse we have mechanical bats; the drones. We have now reached the point where the drones take out moths autonomously, so we are starting to achieve important results.”

Solving problems, Is the charm of innovation

In the meantime, the PATS team now consists of more than 10 people who are engaged daily in the development of the systems, among other things. The PATS team has already delivered ten complete systems to Koppert Cress and Oranjeveld is practically their home. Location manager Paul says: "It's a great team to work with. Their working hours are very different from ours. Sometimes they come in when the rest of us are already done for the day, because for some tests it has to be dark. Other times they have left again before we realize it." As with all start-ups, there are of course still steps to be taken, but solving problems is the charm of innovation. Paul starts to laugh: "Sometimes we come in and realize we lost a few drones. Well, then it is a matter of walking around looking for them. Sometimes we find them and sometimes we don't."

According to Ronald, PATS is an enthusiastic, ambitious and above all serious group of people. "They know what they are doing and where they want to go. I really believe that the Technical University and the Westland area can strengthen each other in this way. I am very curious about the next steps in this project."

---

Website: https://pats-drones.com